Our Latest News

The Role of Diaphragm Valves in Chemical Operations

Diaphragm valves for chemical processing play a critical role in handling aggressive acids, alkalis, and solvents while maintaining system safety and long-term reliability. KDV Flow, with global reach and engineering expertise, provides diaphragm valve solutions engineered to withstand corrosive fluids, elevated temperatures, and abrasive materials without compromising safety or performance....

Valve Solutions for Demanding Conditions in the Oil & Gas

Few sectors operate in environments as severe as oil and gas, where oil and gas ball valves must withstand extreme pressures and corrosive fluids. From upstream exploration to downstream refining, flow control equipment must manage high pressures, aggressive media, and volatile atmospheres while protecting safety and uptime. Across the industry....

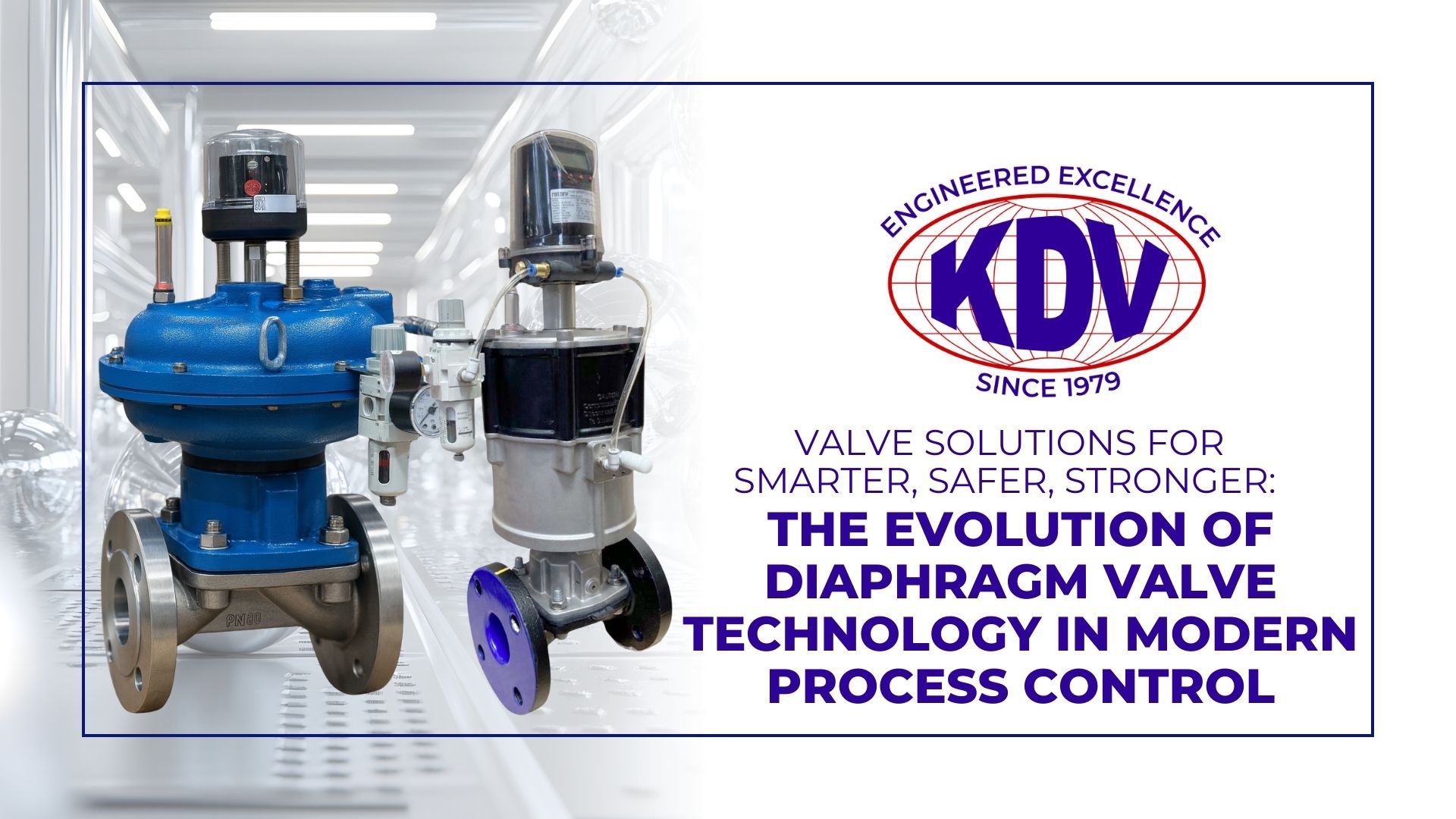

Smarter, Safer, Stronger: The Evolution of Diaphragm Valve Technology in Modern Process Control

Smart diaphragm valves play a central role in controlling flow, ensuring safety, and improving efficiency across industrial systems. As industries continue to adopt digital technologies and demand higher performance, diaphragm valves have evolved beyond their basic shut-off function. KDV Flow is leading this transformation by integrating smart features, enhancing actuator....

Non-Metallic Reliability: Butyl-Lined Diaphragm Valves for Pumping Abrasive Media

Butyl-lined diaphragm valves provide reliable flow control for abrasive and chemically aggressive media in mining, water treatment, and chemical processing. Valves used in these systems must perform consistently while resisting erosion, wear, and chemical degradation. KDV Flow’s butyl-lined diaphragm valves provide an effective, non-metallic solution for controlling flow in harsh....

Reliable Valve Solutions for DN80 Stainless Steel Weir-Type Installations

DN80 stainless steel weir type diaphragm valves remain a preferred choice for engineers managing corrosive and hygienic flow systems. Their design lends itself well to installations where precision flow control, easy maintenance, and resistance to aggressive media are expected. This valve configuration addresses two persistent challenges in the process industry:....

Built to Endure: DN250 Valve Units for Demanding Industrial Service

The DN250 diaphragm valve delivers robust performance and reliable flow control in demanding industrial systems handling corrosive or abrasive media. These units are engineered to support systems operating with corrosive media, abrasive slurries, or high-pressure demands, all while maintaining a consistent seal. A recurring challenge in large-bore pipeline systems is....