metal finishing application

Metal Finishing Industry

KDV Valves, a leading player in the industrial valve sector, plays a pivotal role in metal finishing processes. Industrial valves, integral components in controlling the flow of materials, are essential in ensuring precision and efficiency in these processes.

Our expertise extends to the development and manufacturing of high-quality valves that are crucial in the metal finishing industry. These valves not only regulate the flow of chemicals and materials necessary for treatments like pickling and electroplating but also contribute significantly to maintaining safety and environmental standards.

KDV Valves is not just a provider of industrial solutions; we are a key enabler in enhancing and optimizing industrial operations across numerous sectors.

Operational Benefits of using Lined Valves in Metal Finishing

Plastic Lined Valves: These valves excel in chemical resistance, perfect for the harsh substances used in metal treatments. Their robust construction ensures a consistent, contamination-free flow, essential for maintaining the integrity of the finishing process.

Glass Lined Valves: With their superior corrosion protection, our glass-lined valves are ideal for maintaining the purity of materials. They are especially valuable in processes where contamination control is critical, ensuring a flawless finish.

Stainless Steel Valves: Known for their strength, KDV stainless steel valves withstand the demanding conditions of metal finishing. Their adaptability across various temperatures and pressures makes them indispensable for a seamless and efficient operation.

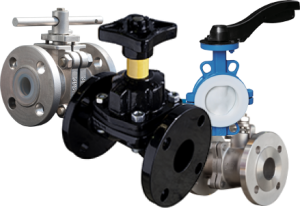

KDV Valve Types and Materials

Advantages of Using Lined Diaphragm Valves:

- The Plastic, Glass, and Stainless Steel options are specifically built to resist the diverse chemical exposures and thermal stresses found in metal finishing.

- Their specialized linings act as a protective shield, enhancing the valve’s durability against harsh processing media.

Advantages of Using Lined Butterfly Valves:

- These valves enable swift shut-off and flow control, essential for the dynamic fluid management in metal finishing operations.

- Durable linings reduce wear from corrosive elements, delivering consistent performance and reducing the need for frequent valve replacements.

Advantages of Using Lined Ball Valves:

- Celebrated for their exceptional sealing capabilities, our ball valves are perfect for applications where zero leakage is essential, such as in controlled metal coating processes.

- The additional lining offers defense against corrosive substances, ensuring long-term valve integrity.

Advantages of Using Lined Check Valves:

- Crucial for preventing reverse flow, these valves play a protective role in metal finishing systems.

- Linings that are resistant to corrosion and wear significantly cut down on maintenance, improving the reliability of the entire system.

Customer Support and Services

KDV is committed to providing not just superior products but also exceptional support and services. Our team of experts is available to assist with valve selection, system design, and after-sales service, ensuring that your operations run smoothly and efficiently.