Mining & Mineral application

Mining and Mineral Industry

KDV Recognising the intricate nature of mineral extraction and processing, we delve into the core stages that define the industry’s backbone. From the initial engagement of leaching reactions, where valuable minerals are skilfully separated from their ores to the precision-driven electrolysis processes for metal refinement, each step is a testament to the blend of chemical expertise and engineering finesse.

Subsequent processes, such as the meticulous recycling of acids and lyes, ensure that the principles of sustainability are woven seamlessly into the fabric of mineral processing. Preconcentration techniques stand as a bulwark for resource conservation, underpinning the economic and environmental ethos of the industry.

Our approach is not merely about facilitating these complex processes but empowering them. With a keen focus on the latest advancements and a commitment to process optimisation, we ensure that professionals in the field are equipped with the knowledge and tools to maintain peak operational efficiency, propelling the industry towards a future where precision, sustainability, and innovation converge.

Operational Benefits of using Lined Valves in Mining & Mineral processing

- Plastic Lined Valves: Offer outstanding corrosion resistance, essential for managing the aggressive chemicals prevalent in mineral leaching processes.

- Glass Lined Valves: Provide a non-reactive, smooth surface, minimising contamination risks and ensuring consistent flow during mineral purification.

- Stainless Steel Valves: Renowned for their robustness, these valves excel under the high-pressure and temperature demands of mineral processing, promising extended service life and dependability.

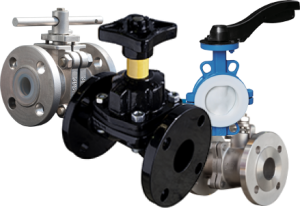

KDV Valve Types and Materials

Advantages of Using Lined Diaphragm Valves:

- Plastic/Glass/Stainless options are tailored for diverse chemical exposures and temperature ranges encountered in mineral processing.

- The linings safeguard the valves from aggressive media, prolonging operational life and reliability.

Advantages of Using Lined Butterfly Valves:

- Designed for rapid shut-off and regulation, crucial for managing material flow in mineral separation.

- Linings provide resilience against wear, extending valve life in the presence of abrasive slurries.

Advantages of Using Lined Ball Valves:

- Renowned for their leak-proof sealing, they are ideal for containment in high-stakes processing where leakage is not an option.

- The linings offer an extra defense against the corrosive substances commonly found in mineral processing.

Advantages of Using Lined Check Valves:

- Essential for preventing reverse flow, they ensure the protection of vital processing equipment.

- The linings diminish the frequency of maintenance by withstanding corrosive and abrasive flows.

Customer Support and Services

KDV is committed to providing not just superior products but also exceptional support and services. Our team of experts is available to assist with valve selection, system design, and after-sales service, ensuring that your operations run smoothly and efficiently.