Food & beverage application

Food and Beverage Industry

Food and beverage processing is a sophisticated and critical component of the industry’s supply chain, requiring a nuanced understanding of both the engineering principles and the biochemical dynamics that underpin the transformation of raw materials into consumable products. As valve manufacturer, we recognize the importance of each stage—from the initial raw material handling to the intricate control of processing parameters, ensuring that the final product meets stringent quality and safety standards.

Central to maintaining the integrity of these processes is the implementation of Clean-In-Place (CIP) systems. These systems are engineered to provide thorough and repeatable cleaning cycles, crucial for the prevention of microbial and cross-contamination, and ensuring product consistency. By integrating advanced sensors and control logic, CIP processes can be closely monitored and adjusted in real-time, ensuring that cleaning is both effective and efficient, adhering to the rigorous standards expected in our industry.

Operational Benefits of using Lined Valves in Food & Beverage processing

- Plastic Lined Valves: Offers excellent corrosion resistance and is suitable for handling a wide range of fluids. These are cost-effective and have a lower risk of product contamination.

- Glass Lined Valves: Ideal for maintaining the purity of the product as they are non-reactive. They can withstand a wide range of temperatures and are easy to clean, supporting stringent hygiene standards.

- Stainless Steel Valves: Known for their strength and durability, stainless steel valves can handle high pressures and temperatures, making them suitable for a variety of processes in the food and beverage industry.

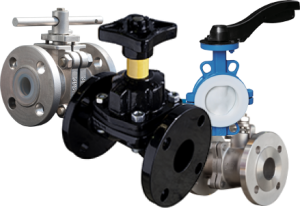

KDV Valve Types and Materials

Advantages of Using Lined Diaphragm Valves:

- Plastic/Glass/Stainless options cater to a variety of chemical exposures and temperatures.

- The lining protects the valve from aggressive media, extending service life.

Advantages of Using Lined Butterfly Valves:

- They offer quick shut-off and modulating capabilities, essential for flow control in papermaking.

- The lining ensures minimal wear and tear from abrasive materials.

Advantages of Using Lined Ball Valves:

- Known for their tight sealing capabilities, they are perfect for processes requiring zero leakage.

- The lining provides an additional layer of protection against corrosive substances.

Advantages of Using Lined Check Valves:

- They prevent backflow, protecting critical components of the system.

- The lining reduces maintenance needs by resisting corrosive and abrasive materials.

Customer Support and Services

Our commitment to customer satisfaction extends beyond the sale of our products. We offer comprehensive support and services to ensure that our valves operate efficiently and effectively within your processes. From installation guidance to maintenance and repair, our team is dedicated to providing the expertise you need.