Pulp & paper applications

Pulp and Paper Industry

KDV Valves recognizes that each stage of paper production is a complex interplay of variables. The transformation from raw cellulose fibers into high-quality paper products is an intricate ballet of precision engineering and chemical mastery. Subsequent stages, such as bleaching, where lignin is meticulously removed without compromising fiber strength, and sheet formation, where the delicate balance of water content and fiber alignment is achieved, are critical in defining the end product’s properties.

Our valves are not just facilitators but enablers of fine control and process optimization. Designed to withstand the demanding conditions of pulp and paper processing, our valves ensure that the flow of materials is managed with precision, safeguarding the integrity of the process and the quality of the paper produced.

Operational Benefits of using Lined Valves in Pulp & Paper processing

Our valves are not just components; they are engineered solutions that offer significant operational benefits:

- Plastic Lined Valves: Offer superior corrosion resistance, ideal for harsh chemicals used in pulping and bleaching processes.

- Glass Lined Valves: Provide a smooth, non-stick surface, reducing the risk of blockages and ensuring a steady flow of materials.

- Stainless Steel Valves: Known for their strength and durability, these valves withstand high pressures and temperatures, ensuring longevity and reliability.

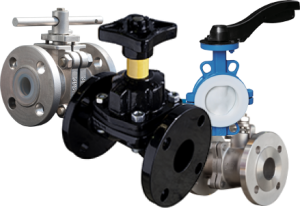

KDV Valve Types and Materials

Advantages of Using Lined Diaphragm Valves:

- Plastic/Glass/Stainless options cater to a variety of chemical exposures and temperatures.

- The lining protects the valve from aggressive media, extending service life.

Advantages of Using Lined Butterfly Valves:

- They offer quick shut-off and modulating capabilities, essential for flow control in papermaking.

- The lining ensures minimal wear and tear from abrasive materials.

Advantages of Using Lined Ball Valves:

- Known for their tight sealing capabilities, they are perfect for processes requiring zero leakage.

- The lining provides an additional layer of protection against corrosive substances.

Advantages of Using Lined Check Valves:

- They prevent backflow, protecting critical components of the system.

- The lining reduces maintenance needs by resisting corrosive and abrasive materials.

Customer Support and Services

Kim Diaphragm Valves (KDV) is committed to providing not just superior products but also exceptional support and services. Our team of experts is available to assist with valve selection, system design, and after-sales service, ensuring that your operations run smoothly and efficiently.