Power application

Power Industry

In the dynamic world of power generation, KDV Valves stands at the forefront, understanding that each phase of power plant processing is a sophisticated fusion of variables. The journey from raw chemical elements to the seamless production of energy is a complex symphony of precision engineering and chemical acumen. Key processes such as the conditioning of process water, where chemicals are expertly balanced to optimize thermal efficiency, and the management of corrosive fluids in flue gas pressurization, are pivotal in maintaining the robustness of the operation.

Our valves are more than mere components; they are the architects of meticulous control and process refinement. Crafted to meet the rigorous demands of power plant operations, our valves deliver precise management of material flows, ensuring the integrity of the process and the excellence of energy production.

Operational Benefits of using Lined Valves in Power processing Industry

Plastic Lined Valves: Combat corrosion with our cost-effective, leak-resistant plastic-lined valves, ensuring longevity in aggressive environments.

Glass Lined Valves: Opt for our glass-lined valves for a flawless operation, offering superior resistance to corrosives with minimal maintenance.

Stainless Steel Valves: Trust in the robustness of our stainless steel valves, designed to withstand the rigors of high-pressure, high-temperature processes.

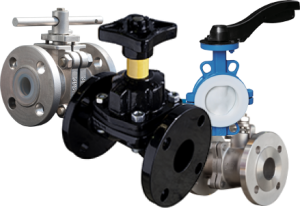

KDV Valve Types and Materials

Advantages of Using Lined Diaphragm Valves:

- Plastic: Exceptional chemical resistance and economic efficiency.

- Glass: Inert properties ensure product purity and longevity.

- Stainless Steel: Robust construction for high-pressure resilience.

Advantages of Using Lined Butterfly Valves:

- Plastic: Lightweight and corrosion-resistant for versatile use.

- Glass: Smooth operation with minimal maintenance required.

- Stainless Steel: Endurance in extreme conditions without compromising performance.

Advantages of Using Lined Ball Valves:

- Plastic: Cost-effective and reliable for chemical applications.

- Glass: High purity levels and resistance to contamination.

- Stainless Steel: Superior strength and longevity in harsh environments.

Advantages of Using Lined Check Valves:

- Plastic: Corrosion-resistant and ideal for a wide range of chemicals.

- Glass: Ensures a pure flow with minimal risk of contamination.

- Stainless Steel: Provides a robust solution for high-pressure systems.

Customer Support and Services

KDV is committed to providing not just superior products but also exceptional support and services. Our team of experts is available to assist with valve selection, system design, and after-sales service, ensuring that your operations run smoothly and efficiently.