Special Chemical application

Special Chemical Industry

In the dynamic and demanding sectors of crop science, coatings production, and power plant operations, the role of specialty chemicals is pivotal. At KDV, we specialize in providing process engineering solutions that not only meet industry standards but also excel in performance, sustainability, and eco-compliance.

In Crop Science, our emphasis is on harmonizing high yields with environmental stewardship. For Coatings and Pigments, we assure longevity, functional superiority, and enhanced aesthetic value. In Power Plant Processing, our commitment to precision and quality guarantees efficient integration and consistent results.

Operational Benefits of using Lined Valves in Special Chemical processing Industry

Plastic Lined Valves: These valves excel in resisting corrosive substances, ensuring a pure and uncontaminated flow vital for the integrity of chemical manufacturing.

Glass Lined Valves: With exceptional corrosion resistance, our glass-lined valves are indispensable for processes where material purity is paramount, contributing to the impeccable quality of chemical products.

Stainless Steel Valves: Renowned for their durability, KDV stainless steel valves withstand the demanding requirements of special chemical processing, offering versatility and reliability for a seamless and efficient workflow.

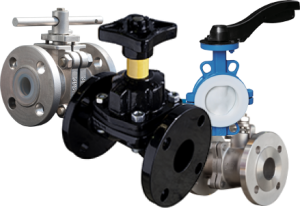

KDV Valve Types and Materials

Advantages of Using Lined Diaphragm Valves: Withstand diverse chemical interactions and temperature variations, extending lifespan in aggressive environments.

- Plastic, glass, and stainless steel linings are engineered to endure the diverse chemical interactions and temperature variations prevalent in special chemical processes. These linings function as robust barriers, extending the valve’s lifespan in aggressive processing environments.

Advantages of Using Lined Butterfly Valves: Enable rapid shut-off and precise flow control, with linings that resist degradation from corrosive agents.

- Our butterfly valves facilitate rapid shut-off and precise flow management, vital for the dynamic fluid handling required in special chemical operations. The resilient linings mitigate degradation caused by corrosive agents, ensuring dependable operation and minimizing the need for frequent valve replacement.

Advantages of Using Lined Ball Valves: Known for superior sealing, ideal in sterile environments with linings that guard against corrosives.

- Renowned for their superior sealing properties, our ball valves are ideal for situations where absolute tightness is crucial, such as in the sterile environments of special chemical manufacturing. The additional lining serves as a defence against corrosive materials, preserving the valve’s integrity over time.

Advantages of Using Lined Check Valves: Prevent backflow effectively, with corrosion and abrasion-resistant linings reducing maintenance needs.

- Essential for preventing backflow, these valves act as safeguards in special chemical systems. Linings resistant to corrosion and abrasion significantly reduce maintenance requirements, reinforcing the reliability of the entire operation.

Customer Support and Services

KDV is committed to providing not just superior products but also exceptional support and services. Our team of experts is available to assist with valve selection, system design, and after-sales service, ensuring that your operations run smoothly and efficiently.