KDV Flow expands ETFE Lining Capabilities

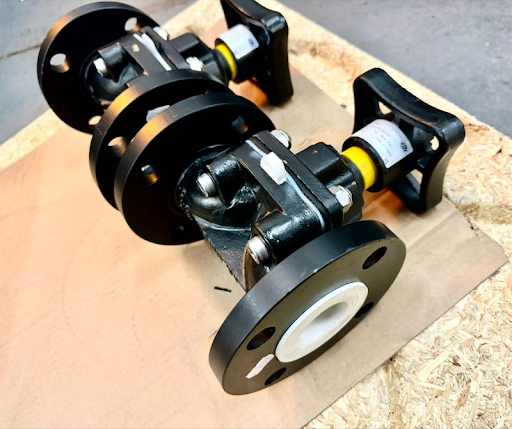

KDV Flow, a recognized global leader in valve technology, is pleased to announce a significant expansion of our ETFE (ethylene tetrafluoroethylene) lining capabilities for diaphragm valves. This strategic enhancement, facilitated by our upgraded manufacturing facility in Thailand, solidifies our commitment to providing cutting-edge solutions for industries facing challenging corrosive environments.

ETFE Linings: The Ultimate Defense Against Corrosion:

ETFE Ethylene tetrafluoroethylene (ETFE) is a fluorine-based plastic. A high-performance fluoropolymer renowned for its exceptional resistance to a wide spectrum of corrosive chemicals, acids, bases, and solvents. By lining our diaphragm valves with ETFE, we create an impenetrable barrier that protects the valve’s metal components, significantly extending service life and minimizing maintenance requirements.

Benefits of ETFE Lining:

- Superior Product Purity: Ideal for pharmaceutical, semiconductor, and food processing applications where contamination cannot be tolerated.

- Enhanced Durability: Exceptional resistance to abrasion and wear, especially in applications involving slurries or abrasive media.

- Thermal Stability: Maintains structural integrity even under extreme temperature fluctuations.

What is the Life Expectancy of a Diaphragm Valve if Lined with ETFE?

The life expectancy of a diaphragm valve can vary depending on the application and operating conditions. You might be asking yourself, how can I ensure these valves last as long as possible in my system? The key lies in selecting the right materials and adhering to proper maintenance practices. When fitted with ETFE (Ethylene Tetrafluoroethylene) linings, diaphragm valves become markedly more durable and resistant to corrosion, potentially extending their lifespan to many years, even in the most demanding environments. For example, valves with ETFE linings have been shown to last up to three times longer than standard valves in highly corrosive conditions. Regular maintenance and correct usage can further enhance their longevity, ensuring reliable performance over an extended period.

Types of Diaphragm Valves with ETFE Lining

Diaphragm valves with ETFE (Ethylene Tetrafluoroethylene) linings are highly sought after in industries where chemical resistance, durability, and hygiene are paramount. ETFE linings significantly enhance the valve’s performance, making them suitable for a wide range of demanding applications. Here are the common types of diaphragm valves available with ETFE linings:

- Weir Type Diaphragm Valves:

Featuring a raised weir, these valves are ideal for controlling the flow of slurries, viscous fluids, and other challenging media. The ETFE lining provides superior resistance to corrosive substances, making these valves well-suited for applications in chemical processing, pharmaceuticals, and other industries where contact with aggressive fluids must be minimised. The weir design helps reduce contact with the diaphragm, extending the valve’s lifespan and maintaining the integrity of the fluid being processed. - Straight-Through Diaphragm Valves:

Designed for applications requiring minimal flow resistance, straight-through diaphragm valves with ETFE linings are often employed in water treatment, food processing, and other industries where an unobstructed flow path is crucial. The ETFE lining ensures that the valve can handle a variety of aggressive chemicals without compromising the purity of the fluid. These valves are particularly beneficial in systems where maintaining a high flow rate with minimal pressure drop is essential. - Hygienic Diaphragm Valves:

These valves are specifically designed for use in industries such as food and beverage, pharmaceuticals, and biotechnology, where sterility and cleanliness are critical. The ETFE lining provides a non-reactive surface, ensuring that the valve does not contaminate the product or alter its properties. Hygienic diaphragm valves are commonly used in clean-in-place (CIP) and sterilise-in-place (SIP) systems, where they offer excellent resistance to the cleaning agents and high temperatures involved in these processes. - Zero Dead-Leg Diaphragm Valves:

Often used in biopharmaceutical applications, zero dead-leg diaphragm valves with ETFE linings are designed to eliminate areas where fluid could become trapped, which is crucial for maintaining sterility and preventing contamination. The ETFE lining adds an extra layer of protection against corrosive and reactive chemicals, ensuring that the valve maintains its integrity over extended periods of use.

What Are Diaphragm Valves with ETFE Lining Primarily Used For?

You might be wondering why ETFE-lined diaphragm valves are the preferred choice in so many critical applications. The answer lies in their ability to provide precise fluid control while offering unmatched chemical resistance and durability. These valves are primarily used in industries where maintaining product purity and avoiding contamination are essential, including:

- Pharmaceutical Production:

Diaphragm valves with ETFE linings are essential for ensuring sterile and contamination-free environments, offering precise flow control and resisting the harsh cleaning agents used in pharmaceutical manufacturing. - Food and Beverage Processing:

In food and beverage production, these valves play a crucial role in maintaining hygiene and ensuring the safe, efficient flow of ingredients and products. The ETFE lining prevents any interaction between the valve and the food substances, preserving their purity. - Water Treatment:

ETFE-lined diaphragm valves are vital in water treatment systems, where they manage the flow of both clean and waste water. The lining ensures the valves can handle the chemicals used in water treatment without degrading, providing long-lasting performance. - Chemical Processing:

These valves are designed to safely handle corrosive and abrasive chemicals, protecting both the environment and the equipment. The ETFE lining offers exceptional resistance to a wide range of aggressive substances, making these valves indispensable in chemical processing plants.

KDV’s Increased Production Capacity and Customization:

Our state-of-the-art injection molding facility in Thailand enables us to produce ETFE-lined valves with unparalleled precision and efficiency. This expanded capacity ensures faster turnaround times while maintaining our unwavering commitment to quality. Additionally, we offer a wide range of customizable lining thicknesses and configurations to meet the specific needs of diverse industrial applications.

The KDV Flow Advantage:

When you choose KDV Flow, you’re not just getting a valve; you’re gaining a partner committed to your success. We offer:

Decades of expertise in valve design and manufacturing

A global network of support and service

Continuous investment in research and development to bring you the latest advancements in valve technology

To explore the benefits of ETFE-lined diaphragm valves for your specific application, or to learn more about our comprehensive range of valve solutions, please visit our website or contact our sales team. We look forward to collaborating with you to achieve optimal performance, efficiency, and reliability in your operations.